Energy

Energy

Energy drives economies and sustains societies. Energy growth is directly linked to well-b...

Continue Reading

Ship Construction

Ship Construction

We have historical expertise in this sector and Turkish marine sector is one of the top fi...

Continue Reading

Construction

Construction

We become a solution partner in large projects such as buildings, bridges, airports and st...

Continue Reading

Repair and Maintenance

Repair and Maintenance

We become a solution partner in large projects such as buildings, bridges, airports and st...

Continue Reading

Automotive and Transportation

Automotive and Transportation

We offer effective solutions to the automotive, railway and trailer industries with the we...

Continue Reading

Education

Education

Education for Gedik brand is a paramount activity to raise not only exceptional engineers...

Continue Reading

What is Seamless Flux Cored Wire?Flux Cored Wires can be produced in two different ways as seamed and seamless. Seamed cored wires are produced by first rolling/forming the steel strip into a "U" shape in the forming machine as in the production of welded pipes and then putting the powder-mix “core” into it and then closing it into a pipe form and drawing it. On the other hand, seamless cored wires are produced by filling the core into a previously formed steel pipe and drawing it to the desired end-product diameter. With the advancement of technology, a faster and more efficient seamless cored wire production process has been developed. In this method, the core is filled into the U-shaped strip as in the production of seamed cored wires, then the strip is rolled into a circular form and the edges are welded seamlessly with a laser beam. Since there is no gap in the seamless cored wires, contrary to the seamed cored wires, the risk of moisture absorption of the core is automatically eliminated. TYPES OF FLUXCORED WELDING WIREWhat are the advantages of Seamless Cored Wire?In Seamless Cored Wires, the risk of hydrogen-induced cracks is minimized as the seamless design prevents re-absorption of moisture. Since seamless cored wires have very low moisture contents in the core and it is virtually impossible to pick up moisture under normal storage and operation conditions, the need for special vacuum packaging is eliminated.Another advantage of Seamless Cored Wires is the possibility of copper coating. Copper coating protects the wire surface against corrosion, prevents friction in the passage through the liner and contact tip during welding and greatly enhances wire feedability. Finally, thanks to the copper coating, the electrical resistance between the wire and the contact tip is considerably low, resulting in a much more stable arc, cooler contact tip and nozzle, thus in turn, reducing nozzle wear and cooling requirements.Since the production of Laser Welded Seamless Flux Cored Wire requires a distinct technology, knowledge, know-how and experience, the number of companies in the world that can offer products with premium quality still is very limited. Gedik Welding is proud to be the only leading and pioneering company in this field in Turkey and has taken its prestigious position in global competition to a higher level.

GeKaWeldSim Welding simulators based on Virtual or Augmented reality (VR or AR) system are systems that provide an extremely close to reality welding experience consisting of welding machine, welding mask, welding table, welding electrode holders in original shapes and weights, MIG / MAG and TIG torches. The systems, which can simulate the welds made in different welding methods one-to-one, detect and analyze the errors made during welding, are especially preferred for training purposes in educational institutions and industrial enterprises that want to train welders.Since there is no consumption of consumables and main materials to be welded in welding simulators, training costs are minimized, while occupational safety risks that may occur during training are eliminated.With Welding Simulators, Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW-GTAW), Flux Cored Arc Welding (FCAW) processes can be simulated in full detail. Parameters such as feed speed, feed angle, working angle, arc length distance, position, distance between the contact nozzle and the workpiece can be monitored live on the analysis screen, while welding defects such as insufficient penetration, slag inclusion, burning groove, porosity, poor drop placement, excessive convexity / concavity, incorrect weld size, excessive spatter can be monitored and reported together with their location on the seam, providing a detailed performance analysis.

SMART CHOICE FOR UNDERWATER In recent years, more than 50 percent of developed oil deposits and natural gas pipelines are located under the sea, increasing offshore development to develop and exploit mineral resources. Underwater welding plays a special role in the maintenance and repair of modern offshore installations, pipelines and ships. The large amount of underwater structures used in oil and gas production and the increasing intensity of maritime transportation constitute the technological cornerstone of economic development and strategic issues. Gedik Welding has produced Turkey's first domestic underwater welding electrodes as a product of its long years of knowledge and experience in the welding industry. These electrodes have been designed and formulated to produce welding metal with unrivaled, high-performance standards in the field for structural underwater wet welding in all sectors, including offshore oil and gas pipelines, commercial vessels, coastal industries and nuclear facilities. It is available for assembly and repair welding in water depths up to 20 m for offshore and harbor construction, shipbuilding and underwater engineering.Meets Class A Source CriteriaMetal arc welding with covered electrodes with rutile character is the most common underwater welding method used. GeKa UW E7014 is a rutile covered electrode developed for underwater welding with a waterproof coating. AWS A5.35/A5.35M: 2015 standard requirement and AWS D3.6M:2017 Class A quality level. A premium underwater welding electrode with excellent properties that fulfills the "Class A" welding criterion in all positions for both inside fillet and butt welds of pipe and sheet joints according to the international AWS D3.6M:2017 standard. The electrode consists of a specially formulated high efficiency rutile coating that offers a continuous weld seam.Waterproof CoatingThe electrode cover needs to be protected from the water environment by a waterproof coating. In order for underwater welding electrodes to provide high quality weld metal, the waterproof coating is expected to prevent moisture from penetrating the electrode cover, while at the same time allowing it to burn without undue interference with metal transfer. The waterproof coating protects the electrode cover from water and moisture. It also provides the highest level of protection against physical damage to the electrodes, while providing electrical protection for the diver underwater. The soft breakable electrode tip prevents contact of the electrode cover with water, even if it has to remain underwater until welding. Thus, the electrode continues to retain its rutile cover properties during welding. GeKa UW E7014 electrodes are comfortable to use in both fresh and salt water, perform exceptionally well in any position and are specially designed to produce high quality welds at different depths on a variety of carbon steels. With its outstanding user-friendly features and enabling long working times underwater, GeKa UW E7014 is destined to become the electrode of choice for professional welders worldwide. More stable burning and less spatter during welding than other underwater welding electrodes. Easy slag cleaning for the welder. The electrode is easy to re-ignite and the molten metal deposition rate is highly efficient and excellent seam appearance is achieved.Effective and fast solutionInternational interests to develop and exploit the oceans and their mineral resources have allowed the development of offshore gas and oil fields, offshore construction and hence underwater resource development. Underwater welding has been used for construction and maintenance work, but mostly for temporary repair work. Failure of parts underwater can be caused by collisions of ships, unexpected accidents or corrosion. Underwater welding is an effective and fast solution as it can be done immediately after the accident without the need to remove the structure from the water. Underwater welding is also applied in the manufacture of large ships and offshore structures that do not fit into the dock. Underwater welding is also applied to the installation and maintenance of pipelines. GeKa UW E7014 electrodes are available in Ø3,20 and Ø4,00mm. Welding should be performed in accordance with the parameters specified in the catalog.Protective equipment and diving equipment in accordance with occupational safety rules must be used before all stages of use. The most important issue in underwater welding is the availability of welding and welding safety equipment. Due to the high safety risks, great importance and responsibility for carrying out these activities lies with trained human resources, including surface divers and the organizational team. GeKa UW E7014 electrodes are designed to be used in all positions, even for less experienced divers. At the same time, in the hands of more experienced divers, welding can be performed allowing a friendly, controllable arc characteristic. Welding pliers and torches should be as insulating as possible, allowing as little current to escape as possible. Attention should be paid to the angle and height of the grip in welding due to the effect of pressure under water. Attention should be paid to the applicability and accuracy of welding positions.

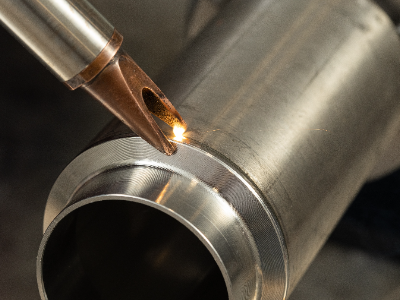

Fast and Efficient: The Power of Laser Welding Technology!Laser welding technology, which is rapidly increasing in use due to its fast and efficient compared to conventional welding methods, enables welding and cutting with low heat input and minimal deformation.Easy to Use, No Professional Knowledge Required: Laser Welding AdvantagesIt is very easy to use and eliminates the need to be an experienced welder as it does not require professional knowledge and experience to weld. The fact that it is much faster than traditional welding methods is one of its salient features.Environmentally Friendly and Energy Efficient: The Environmental Contribution of Laser WeldingThe laser's photoelectric conversion efficiency results in up to 30% less energy consumption and is therefore environmentally friendly. Thanks to the very low heat input in the laser welding process, penetrating, deformation-free and resistant welds can be obtained even in the thinnest materials.Fiber laser welding machines, which are available in our product range with 3 different power options as GeKaLaser 1000, GeKaLaser 1500, GeKaLaser 2000, offer the possibility of cutting and cleaning as well as joining various materials such as unalloyed steel, stainless steel, aluminum, copper, brass with the 3IN1 feature, while eliminating additional labor costs as there is no need for leveling and grinding processes after welding with continuous welding mode.Precise Solutions for Different SectorsOur GeKaLaser Laser Welding machines offer precise solutions in many applications and sectors such as industrial kitchen manufacturing, furniture shelf and scaffolding manufacturing, machinery manufacturing, railing and window manufacturing, advertising and lighting sector, automotive, medical, aviation sector.

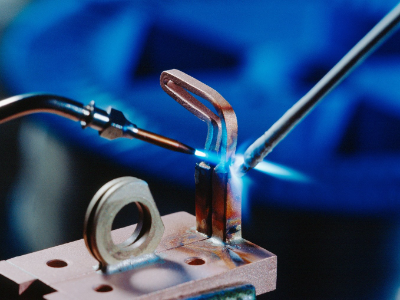

What is Brazing, How Is It Done?The joining of different or same type metals with a heat source using an additional solder alloy that melts above 450 °C is called brazing. The joining process takes place with the metallurgical bond formed by the transfer of atoms called diffusion between the additive metal and the metals to be combined.Where is Brazing Used?The brazing process allows the economical joining of different types of materials with different cross-sectional thicknesses. Therefore, it is preferred in many sectors such as automotive, white goods, aviation and space industry, heating-ventilation, gas armatures production, food sector, and medicine sector. It is also widely used in pipe connections carrying oil, air and fuel where impermeability is important.In brazing joints, in the metals to be joined, unlike welding, melting does not occur. Since there is no significant change in the crystal structure of the material, the homogeneity of the internal structure of the metal is preserved. As the brazing temperature is above 450 °C and lower than the melting temperatures of the soldered metals, deformations caused by high temperatures do not occur in the welded joints.The molten metal solidifies by spreading between the parts to be brazed by capillary action (with capillary tube forces). It is recommended that in order to take advantage of the capillary effect, the spacing of the parts to be brazed should be set between 0.05-0.5 mm. In larger soldering intervals, the capillary effect cannot be benefited from. All elements that will prevent the attachment and flow of the additive metal between the material surfaces to be joined should be removed before the brazing process. Elements such as oil, rust, and paint on the material surface cleaned by brush, sandpaper or suitable chemical methods should be taken to the brazing process without waiting for too long.When the brazing process of the surface-cleaned materials is started, oxide formation starts on the surfaces due to the heat. Fluxes are used to prevent and clean this oxide formation. Fluxes melt 50 °C before the operating temperature, increasing the fluidity of the additive metal while cleaning the oxide.The selection of fluxes that prepare the melt joint zone for brazing before the filler metal is made according to the filler metal. While GeKaTec FLUX F-SH1 fluxes are used for the use of silver alloy brazing rods, it will be appropriate that GeKaTec FLUX F-LH1 fluxes are preferred for brazing aluminum and its alloys. The selection of these related fluxes is determined by the melting temperatures of the materials to be brazed.Self-flux coated brazing rods such as GeKaTec L-Ag20 FC or GeKaTec L-Ag40 FC provide convenience to the user in practice. In addition, since GeKaTec S5 brazing rods, which are frequently preferred, have very high fluidity, they can be used without flux in joining copper to copper.In the selection of the additive metal, it is desired that the melting point of the main metal be at least 200 °C higher than the melting point of the additive metal. Color compatibility can also appear to us as an important criterion in the selection of additional filler materials that are expected to match the mechanical properties of the main material to be brazed.Flame Types in Oxy-Gas Flame BrazingNeutral Flame: It is the type of flame in which the ratios of combustible gas (acetylene) and oxygen are equal. It is generally preferred for brazing metals such as steel and copper.Carburizing Flame: Flames with high flammable gas ratio are called carburizing flames. Its burning is calmer. Its flame cone is longer than normal flame. It is preferred in brazing of cast irons, in order to prevent oxygen content in brazing of aluminum and its alloys, the surface of which is easily oxidized.Oxidizing Flame: It is the type of flame with high oxygen ratio. Its burning is harsh. The highest temperature values are reached in this type of flame. It is used for brazing brass having zinc evaporation problem.

What is Tungsten Electrode?Tungsten electrodes, which ensure the welding process on the workpiece by carrying the current required for arc formation, stand out among the components in TIG welding. The selection of tungsten electrodes, which vary in current carrying capacity, arc characteristics, service life, re-ignition performance with different alloys, is important for welding performance.Where Is Tungsten Electrode Used?Tungsten electrodes, which are indispensable components of TIG welding, can be used for TIG welding of unalloyed and low alloyed materials, stainless and aluminum, depending on their types. Parameters such as the type of material to be welded and the type of current to be used in welding are important in their selection.Tungsten Electrode Types and their PropertiesGreen (Pure) Tungsten ElectrodesWhile unalloyed, pure tungsten electrodes have advantages over other types of tungsten electrodes in terms of cost, they are used especially in TIG welding of aluminum and magnesium alloys. These electrodes with high arc stability are used with AC current.Gray (2% Cerium Alloy) Tungsten ElectrodesCerium alloy electrodes are particularly used for welding unalloyed and stainless steels. It can be used in both DC and AC current type. While it is more preferred to be used in DC current, it has approximately 35% more current carrying capacity than pure tungsten electrodes in AC current.Although its service life is long, its ignition and re-ignition performance is quite high.It is not radioactive. Therefore, it is more environmentally friendly than Thorium alloy tungsten electrodes.Gold (1.5% Lanthanum Alloy) and Blue (2% Lanthanum Alloy) Tungsten ElectrodesLanthanum alloy tungsten electrodes, which provide very high performance especially at low current values, are called Gold and Blue Tungsten Electrodes according to the amount of lanthanum they contain. Lanthanum alloy tungsten electrodes are not radioactive. Their service life is long and their re-ignition performance is high.Lanthanum alloy tungsten electrodes, which are good for use in automation welding, are suitable for use in both AC and DC currents. It is preferred for welding of unalloyed and stainless steels.Red Tungsten (2% Thorium Alloy) ElectrodesWhile it has a very high current loading capacity thanks to the thorium it contains and is highly resistant to oxidation and pollution. They are easy to ignite and form a more stable arc.Thorium alloy electrodes contain a low amount of radioactive material. It is important for users to pay attention to the points in the SDS form of the product.They are mainly used with DC current. Their service life is long. It is generally preferred for welding carbon steels and stainless steels.